For industrial processors and manufacturers, a composition analyzer can be a crucial instrument in any lab or production line setting.

These analyzers not only can test the makeup, efficacy and quality of products but also assist in evaluating a host of constituents besides moisture including proteins, fats, oils, contaminants, BTU, water activity, carbon content, film thickness and coat weight.

“Due to the range of accurate testing readily available with a composition analyzer, using one can dramatically enhance precision and accuracy. With the right calibrations, operators can employ a composition analyzer during any stage of product development from R&D through production to ensure a quality result. Using one can help to detect harmful contaminants or flaws during development and production before a product reaches consumers,” said John Bogart, Managing Director of Kett US, a manufacturer of a full range of organic composition analyzers.

However, in many cases, utilizing traditional testing methods to determine a sample’s composition can be time-consuming and labor-intensive. This can cause testing, development and quality control costs to skyrocket. The costs of performing tests, delaying operations to wait for results and paying for the purchase and proper disposal of consumable products like reagents and chemicals for testing continue to add up.

Of course, the costs of insufficient testing due to excessively lengthy test cycles can be even greater – if undetected contamination or product flaws leads to recalls and a damaged reputation that hinders sales.

Fortunately, with the right instruments and careful planning, lengthy test cycles can be dramatically cut, saving a substantial amount of time and money, while significantly improving quality control.

“Using cutting-edge instruments like Near Infrared (NIR) composition analyzers that provide almost instant, lab quality test results can make all the difference during development and production. This monitoring can be essential not only for precision and correct composition but also for safety and compliance,” said Bogart. He notes that by simplifying the process, manufacturers can increase the quality of their products from raw input, formulation and processing to end product manufacturing and distribution.

The Many Benefits of Faster Composition Analysis

With conventional, outdated testing equipment, sample preparation can be a labor-intensive process. Even when a sample is ready for composition testing, the work and waiting have only begun.

When testing moisture content with legacy composition analyzers, users can expect to wait between 5 to 15 minutes or more for a reading. When performing more complex chemical testing like water activity, protein, fat and ash content, the wait time extends exponentially. With some composition analyzers, one can expect to wait between 24 and 48 hours when testing for the presence of some constituents.

These testing delays not only slow R&D and product development but also allow any flaws or deficiencies to proceed in production, which can be very costly – particularly if the product is later found to be non-compliant and rejected or recalled. The overall costs of slow test cycles can be even more debilitating to processors and manufacturers when routine or recurrent testing must be performed as part of ongoing quality assurance.

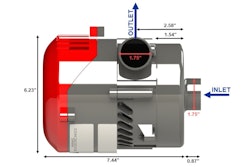

In contrast, a NIR composition analyzer can produce accurate test results in a fraction of the time of traditional methods. Instruments can take a reading over the test subject or product stream for online models as well as desktop models like Kett’s BS-F1700 Compact Fiber Beat Sensor. Light is transmitted through the sample if translucent or transparent or reflected off the process sample with models that measure the amount of light absorbed by the subject. The absorbance readings are then converted into component values by analyzing the composition of the subject based on the instrument’s exact calibrations.

“Today, NIR spectroscopy provides non-destructive laboratory quality readings in real-time. Often, this requires no sample preparation and no contact with the sample. These instruments offer precise, virtually instant readings of moisture, composition analysis, even full-spectrum composition,” said Bogart.

He explains that this kind of full-spectrum testing allows users to measure a broad range of targeted factors in real time, with only initial instrument calibration necessary. Afterward, accurate readings are nearly instantaneous which dramatically reduces the time needed for each test cycle.

Simplifying the process also markedly lowers any ancillary costs related to testing.

“Switching from direct composition analysis to NIR composition analyzers can reduce testing costs by as much as 90% for several reasons,” said Bogart.

He explains that NIR composition analysis cuts the amount of labor and payroll required for each test cycle, eliminates the need to purchase and then pay for the disposal of chemical reagents necessary for testing and dramatically decreases the instances of human error that mandate repeat testing.

Since NIR composition analyzers are designed with speed and accuracy in mind, there is no learning curve for sample preparation. For most models, there is no sample to prepare at all. In some cases, tests can be performed even on the production line without the risk of user error.

The costs are reduced the most for online NIR composition meters that are capable of testing products in real-time during production such as Kett’s KJT700. These models do not need to pause for sample preparation or long test cycles, which could otherwise delay production or even take it offline.

No matter what stage of the product lifecycle processors and manufacturers are focused on, experienced engineers like Kett’s can help them find the right instrument for their specific application.

“To the casual eye, it may seem like there are almost as many composition analyzers out there as there are uses for them, but finding the perfect match for your needs, budget and test cycle length can make all the difference in your outcomes. Working with an experienced partner can help you narrow the field to select a precise, speedy composition analyzer that’s tailored to your specific needs and built to last,” concluded Bogart.